S7-400

The S7-400 is the most powerful PLC in the family of SIMATIC controllers. The S7-400 is an automation platform for system solutions in production and process engineering, and it is characterized primarily by its modularity and performance reserves.

S7-400

• The power PLC for the mid to high-end performance ranges.

• The solution for even the most demanding tasks.

• With a comprehensive range of modules and performancegraded CPUs for optimal adaptation to the automation task.

• Flexible in use through simple implementation of distributed structures.

• User-friendly connections.

• Optimal communication and networking options.

• User-friendly handling and uncomplicated design without a fan.

• Can be expanded without problems when the tasks increase.

• Multicomputing: Simultaneous operation of several CPUs in one S7-400 central controller. Multicomputing distributes the overall performance power of an S7-400. For example, complex tasks can be divided into technologies such as open-loop control, computing or communication, and assigned to different CPUs. And every CPU can be assigned its own local I/O.

• Modularity: The powerful backplane bus of the S7-400 and the communication interfaces that can be connected direct to the CPU enable high-performance operation of a host of communication lines. This enables, for example, division into one communication path for HMI and programming tasks, one for high-performance and equidistant motion control components, and one for a "normal" I/O fieldbus. Additionally required connections to MES/ERP systems or the Internet can also be implemented.

• Engineering and diagnostics: The S7-400 is configured and programmed extremely efficiently together with the SIMATIC Engineering Tools particularly in the case of extensive automation solutions with a high engineering component. For this purpose, high-level languages such as SCL and graphical engineering tools for sequential controls, state graph programs and technologyoriented diagrams are available, for example.

S7-400H

• Fault-tolerant automation system with redundant design.

• For applications with high fail-safety requirements. Processes with high restart costs, expensive downtimes, little supervision, and few maintenance options.

• Redundant central functions.

• Increases availability of I/O: switched I/O configuration.

• Also possible to use I/Os with standard availability: singlesided configuration.

• Hot stand-by: automatic reaction-free switching to the standby unit in the event of a fault.

• Configuration with two separate or one divided central rack.

• Connection of switched I/O via redundant PROFIBUS DP or via system-redundant PROFINET IO.

S7-400F/FH

• Failsafe automation system for plants with increased safety requirements.

• Complies with safety requirements to SIL 3 in accordance with IEC 61508, AK6 in accordance with DIN V 19250 and Cat. 4 in accordance with EN 954-1.

• If required, also fault tolerant through redundant design.

• Without additional wiring of the safety-related I/O.

• Safety-relevant communication via PROFIBUS DP with PROFIsafe profile.

• Based on S7-400H and distributed IOs ET 200M with fail-safe modules.

• Standard modules for non-safety-related applications can also be used in the automation system.

• Isolation module for joint use of fail-safe and standard modules in safety mode in one ET 200M.

Central processing units Standard CPUs

CPU 412

CPU 412-1, CPU 412-2 and CPU 412-2 PN

• The low-cost starter solution for the medium performance range.

• Can be used in small and medium-sized systems with requirements of the medium performance range.

CPU 414

CPU 414-2, CPU 414-3 and CPU 414-3 PN/DP

• CPUs for high demands in the mid-level performance range.

• Applicable for plants with additional demands on programming scope and processing speed.

• Integrated PROFINET functions in CPU 414-3 PN/DP.

CPU 416

CPU 416-2, CPU 416-3 and CPU 416-3 PN/DP

• High-performance CPUs in the high-end performance range.

• Applicable for plants with high requirements in the high-end performance range.

• Integrated PROFINET functions in CPU 416-3 PN/DP.

CPU 417

CPU 417-4

• The most powerful SIMATIC S7-400 CPU.

• Can be used in the most sophisticated installations in the upper performance range.

• With two slots for IF modules.

Central processing units Fail-safe CPUs

CPU 416F-2 and CPU 416F-3 PN/DP

• For constructing a fail-safe automation system for plants with increased safety requirements.

• High-performance CPU in the top-end performance range.

• Complies with safety requirements to SIL 3 acc. to IEC 61508 and PL e acc. to ISO 13849.1.

• Standard and safety-related tasks can be performed with a single CPU.

• Multi-processor mode is possible.

• Safety-related communication with distributed I/O devices over PROFIBUS DP with the PROFIsafe profile.

• Fail-safe I/O modules can be connected decentralized over the integrated interfaces (DP and PN with CPU416F-3 PN/DP) and/or through communication modules (CP443-5 Ext. and CP443-1 Adv.).

• Standard modules for non-safety-related applications can be operated centrally and decentralized.

Central processing units High-availability CPUs

CPU 412-5H, CPU 414-5H, CPU 416-5H, CPU 417-5H

• CPU for SIMATIC S7-400H and S7-400F/FH.

• Can be used in S7-400H high-availability systems.

• Can be used with F runtime license as F-capable CPU in S7-400F/FH safety-related systems.

• With integrated PROFIBUS DP master and combined MPI/PROFIBUS DP master interface.

• With integrated PROFINET interface (2-port switch).

• Features 2 slots for sync modules.

Y-link for S7-400H

• Transceiver for the transition from a redundant PROFIBUS DP master system to a single-channel PROFIBUS DP master system.

• To connect devices with a single PROFIBUS DP interface to the redundant PROFIBUS DP master system of the SIMATIC S7-400H.

Structure of a CPU 41x

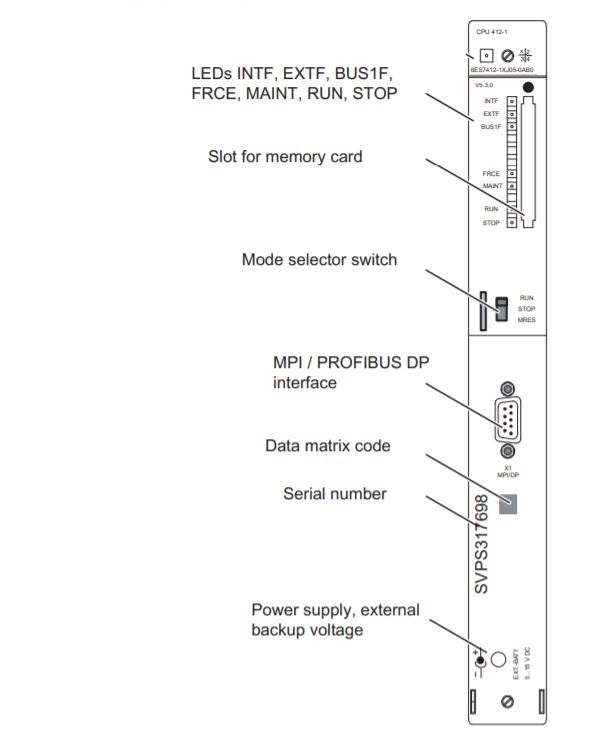

Control and display elements of the CPUs Control and display elements of CPU 412-1

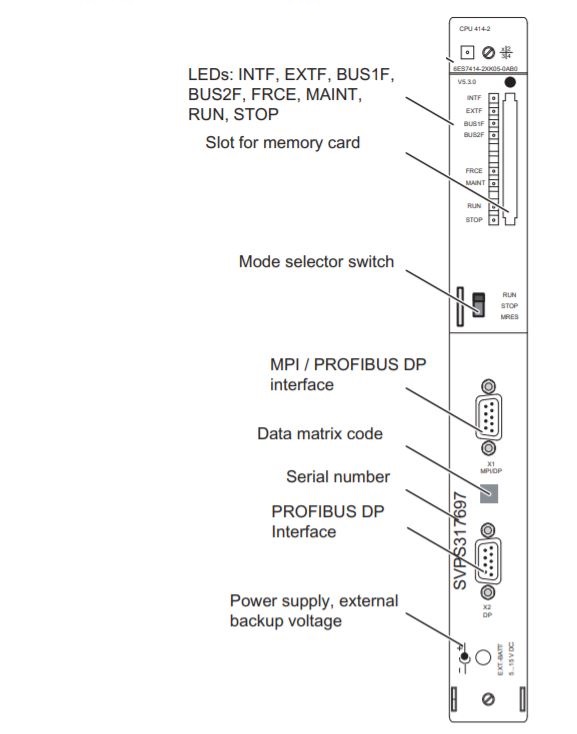

Control and display elements of CPU 412-2 PN

Control and display elements of CPU 41x-2

Control and display elements of CPU 41x-3

Control and display elements of CPU 41x-3 PN/DP

Control and display elements of CPU 417-4

The table below provides an overview of the LEDs on the specific CPUs.

| LED | Color | Meaning | 412-1 | 412-2, 414-2, 416-2, 416F-2 | 414-3, 416-3 | 412-2 PN, 414-3 PN/DP, 414F-3 PN/DP, 416F-3 PN/DP | 417-4 |

|---|---|---|---|---|---|---|---|

| INTF | red | Internal fault | X | X | X | X | X |

| EXTF | red | External fault | X | X | X | X | X |

| FRCE | yellow | Force command active | X | X | X | X | X |

| MAINT | yellow | Maintenance request pending | X | X | X | X | X |

| RUN | green | Run mode | X | X | X | X | X |

| STOP | yellow | Stop mode | X | X | X | X | X |

| BUS1F | red | Bus fault at MPI/PROFIBUS DP interface 1 | X | X | X | X | X |

| BUS2F | vermelho | Bus fault at PROFIBUS DP interface 2 | - | X | X | - | X |

| BUS5F | red | Bus fault at PROFINET interface | - | - | X | X | X |

| IFM1F | red | Bus fault at interface module 1 | - | - | X | X | X |

| IFM2F | red | Bus fault at interface module 2 | - | - | - | - | X |

Unregistered user. Buy the training at jats.com.br.