Soybean Crushing Project

Project – Factory_Prj

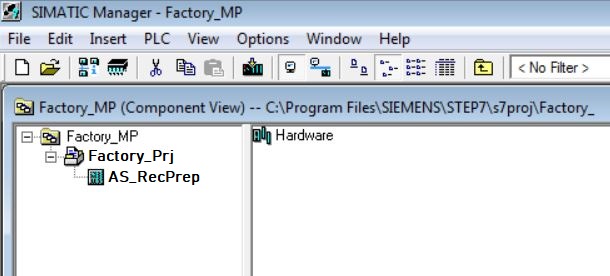

The Factory project contains:

Factory_Prj

• AS_RecPrep

• AS_Processing

• AS_Energy

• Engineering PC Station with WinCC Application – ES

WinCC Application

Plant Bus - IE General – 192.168.0.2

ES – ENGINEERING STATION

Click here to download Project Crushing Soy filesFiles include pictures and SCL files.

Creating the multiproject

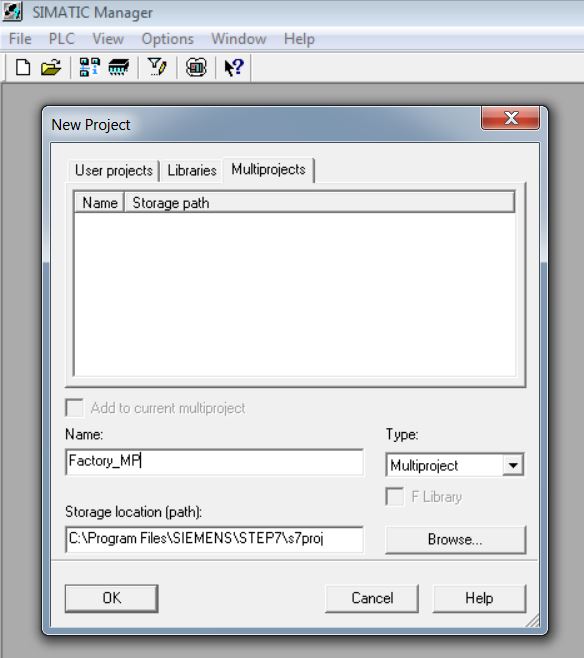

Create Factory_MP multiproject

• Open SIMATIC Manager.

• Select File > New... menu item to create multiproject.

• Select Multiprojects tab.

• Insert Name = Factory_MP for the multiproject. Type = Multiproject. Choose multiproject storage location (standard C:\Programs Files (x86)\SIEMENS\STEP7\s7proj). Click on OK.

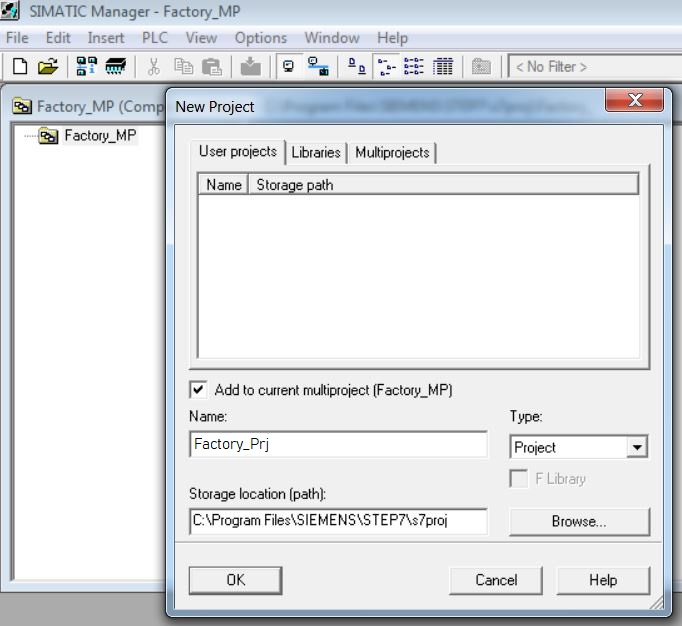

• Create Factory_Prj project to Factory_MP multiproject. In SIMATIC Manager, select File > New... menu item.

• Select User projects tab.

• Insert Name = Factory_Prj for the project. Type = Project. Choose project storage location (standard C:\Programs Files (x86)\SIEMENS\STEP7\s7proj). Select Add to current multiproject (Factory_MP) to include the Factory_Prj project in the Factory_MP multi-project.

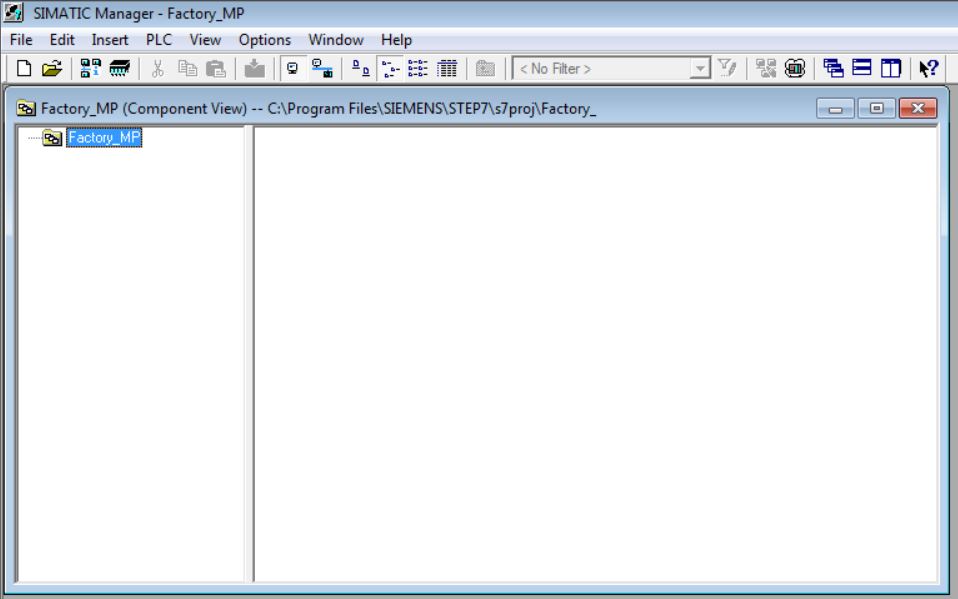

• Close the Factory_Prj project window and work within the Factory_MP multiproject.

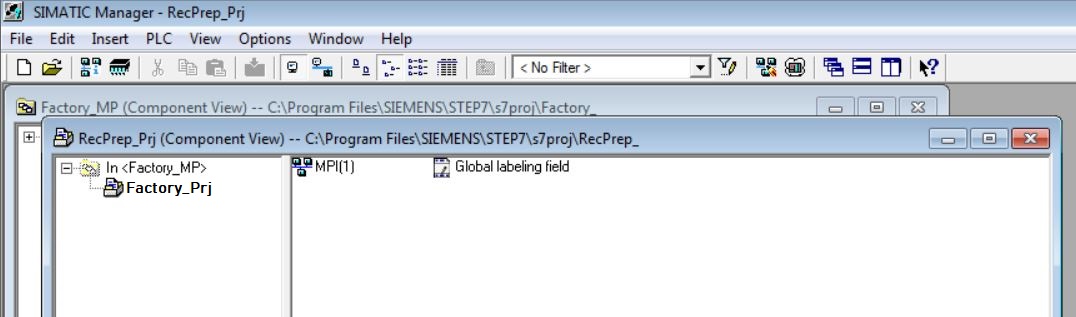

• Insert SIMATIC 400 Station (AS_RecPrep – CPU). Right-click on Factory_Prj and select Insert New Object... SIMATIC 400 Station. Rename to AS_RecPrep.

Opening and closing a Multiproject

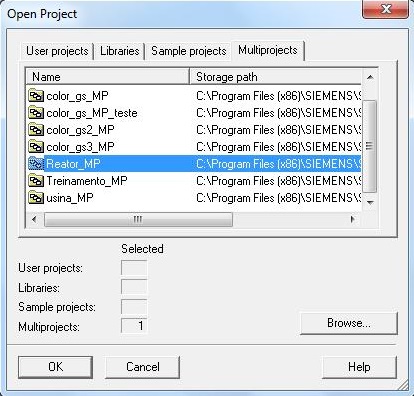

To open a multiproject, select the SIMATIC Manager File > Open menu item. On the Multiproject tab, choose the desired multiproject.

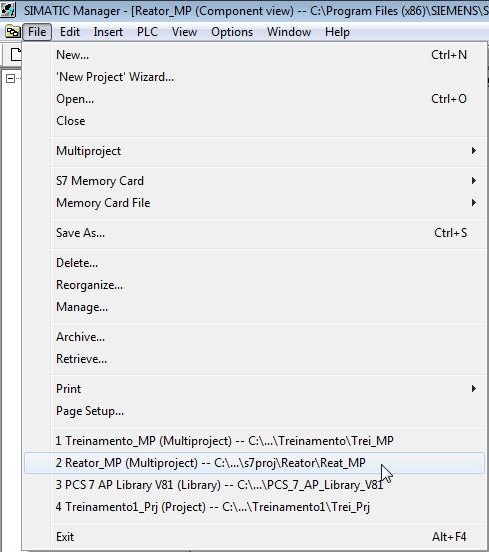

The last multiprojects, projects, or open libraries appear at the end of the File menu to be reopened.

To close a multiproject, choose Close from the File menu of SIMATIC Manager.

Note: If you have any problem creating a project, check:

• whether the network target is configured on the computer or virtual machine;

• verify that the IP address of the computer or virtual machine has been configured;

• check that all indicated software has been installed;

• check that all necessary licenses have been installed;

• disconnect the computer from the internet and disable bluetooth.

Crushing or commonly known as crushing is a crucial technology in the processing of soy beans to obtain oil and bran, the process is basically divided into three distinct steps, one of which is the preparation of the grain, solvent extraction and treatment and storage of the main processed products and by-products. The ideal is for the soybean to have a moisture content of around 13%, for this the first process is drying, then the peel is separated, which is a by-product and can be incorporated into the bran.

The next process is the extraction carried out by equipment called an extractor, after passing through this, the crushed soybean undergoes desolventization, toasting, drying and cooling of the bran. With the extraction process, oil is also obtained which, through the use of solvent and obtained through the simple distillation process, both products from the crushing of soybeans are subsequently treated and stored. The crude oil goes to the degumming process with the objective of reducing its phosphorus content and the bran goes to the milling and adjustment of the granulometry.

The enormous contribution to the modern industrial crushing process in the soybean chain is due to the application of state-of-the-art technology, automation engineering and industrial control, modern machinery and equipment, sensors and actuators, fully automated plants streamlining steps and accurately controlling all equipment and variables involved throughout the process, and put an end to the training and specialized workforce that are essential for the success of the entire operation.

Next

Unregistered user. Buy the training at jats.com.br.