SIEMENS SIMATIC S7 + WINCC

Grid Cleaning Control

Grid Cleaning Control

Cleaning control of the Pin Hole grid is performed sequentially and continuously throughout the boiler operation.

• Create FB10 FB_LIMP_VV Cleaning Valve Function Block.

• Open FB10 for editing. In Component View, double-click on the function block.

• In Interface, enter the input parameters:

| Name | Type | Description | S7_m_c |

|---|---|---|---|

| INICIA | Bool | Sequence start |

• In Interface, enter the output parameters::

| Name | Type | Description | S7_m_c |

|---|---|---|---|

| FINAL | Bool | Sequence final | |

| VV_CA | Bool | Valve automatic command |

• In Interface, enter the IN/OUT parameters:

| Name | Type | Description | S7_m_c |

|---|---|---|---|

| SPTAVV | Int | SP Valve Opening Time | |

| SPTIEVV | Int | SP Valve Interval Time |

• In Interface, enter the STAT parameters:

| Name | Type |

|---|---|

| TIMER1 | TON |

| TIMER1_Q | Bool |

| TIMER2 | TON |

| TIMER2_Q | Bool |

| BIT1 | Bool |

| X1SPTAVV | DInt |

| X2SPTAVV | Time |

| X1SPTEVV | DInt |

| X2SPTEVV | Time |

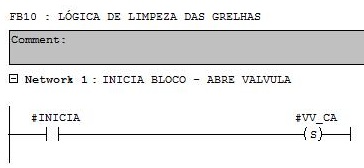

• Start valve cleaning sequence. Open valve in automatic.

• Open valve time count, defined in the STPAVV setpoint by the operator.

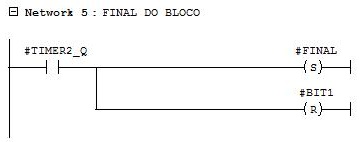

• After the time has elapsed, close the valve automatically and start an interval between valves.

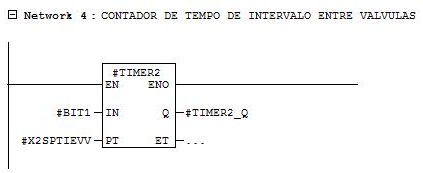

• Counting of cleaning interval between valves, defined in the SPTIEVV setpoint by the operator.

• After the interval has elapsed, complete the valve cleaning sequence.

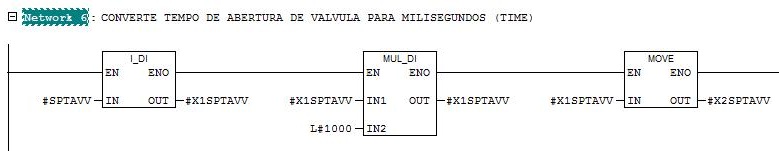

• Conversion of time from the SPTAVV setpoint from the whole type (in seconds, coming from the supervisory) to the Time type (in milliseconds).

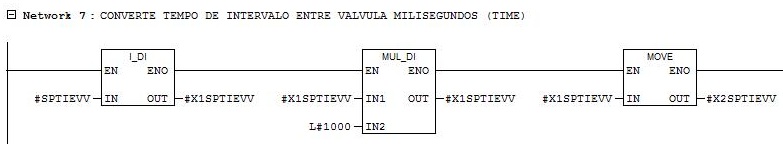

• Time conversion of the SPTIEVV setpoint from the whole type (in seconds, coming from the supervisory) to the Time type (in milliseconds).

• Create FB11 CTR_LIMP_GRELHA Grid Cleaning Control Function Block.

• Open function block FB11 for editing. In Component View, double-click on the function block.

• In Interface, enter the input parameters:

| Name | Type | Description | S7_m_c |

|---|---|---|---|

| SPILG | Int | SP interval between cleanings time | True |

| AM | Bool | Auto/Manual Grid cleaning control | True |

• In Interface, enter the output parameters:

| Name | Type | Description | S7_m_c |

|---|---|---|---|

| TDLG | Int | Elapsed Time Grid Cleaning Interval | True |

| LG_XV351OK | Bool | XV351 cleaning OK | True |

| LG_XV352OK | Bool | XV352 cleaning OK | True |

| LG_XV353OK | Bool | XV353 cleaning OK | True |

| LG_XV354OK | Bool | XV354 cleaning OK | True |

| LG_XV355OK | Bool | XV355 cleaning OK | True |

| LG_XV356OK | Bool | XV356 cleaning OK | True |

| LG_XV357OK | Bool | XV357 cleaning OK | True |

| LG_XV358OK | Bool | XV358 cleaning OK | True |

| LG_XV359OK | Bool | XV359 cleaning OK | True |

• In Interface, enter the input/output parameters:

| Name | Type | Description | S7_m_c |

|---|---|---|---|

| SPTAVV | Int | SP Valve Opening Time | True |

| SPTIEVV | Int | SP Valve Interval Time | True |

• In Interface, enter the STAT parameters:

| Name | Type |

|---|---|

| T1 | TON |

| SPILGDINT1 | DInt |

| SPILGDINT2 | DInt |

| SPILGTIME | Time |

| TDLGTIME | Time |

| TDLGDINT1 | DInt |

| TDLGDINT2 | DInt |

| P1LG | Bool |

| X1LG | Bool |

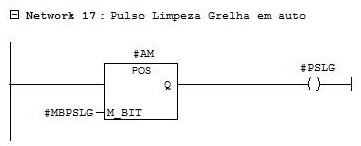

| MBPSLG | Bool |

| PSLG | Bool |

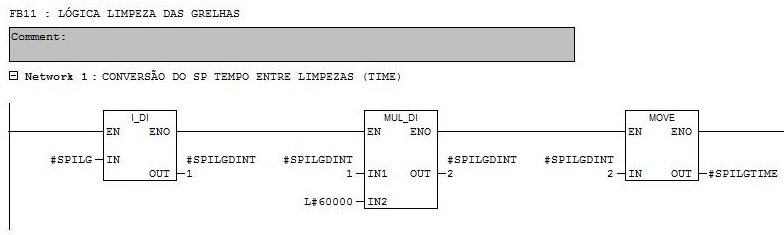

• Time conversion of the SPILG setpoint from the whole type (in minutes, coming from the supervisory) to the Time type (in milliseconds).

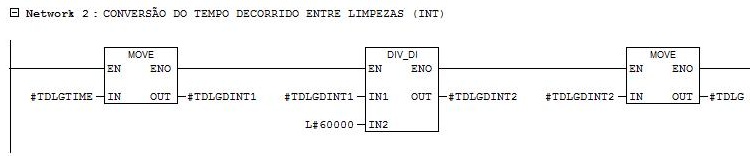

• Conversion of time elapsed between cleaning intervals, from the time type (in milliseconds) to the int type (sent to the supervisory).

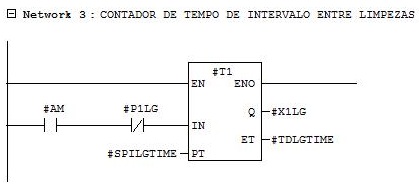

• Interval time count between cleanings.

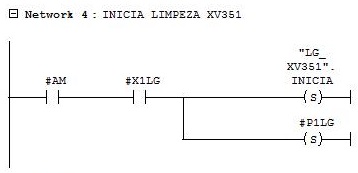

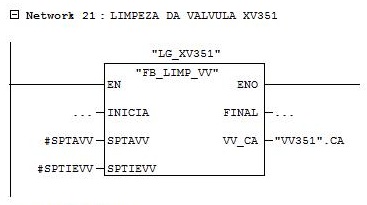

• After the interval between cleaning has elapsed, start cleaning the XV351 valve.

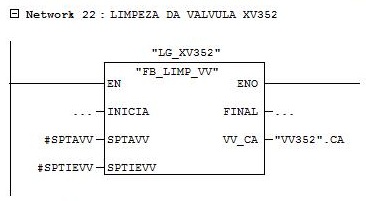

• After the cleaning sequence for the XV351 valve is finished, start cleaning the XV352 valve.

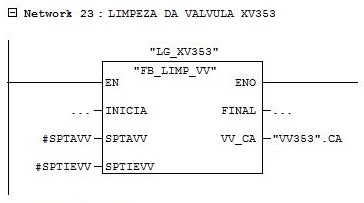

• After the cleaning sequence for the XV352 valve is finished, start cleaning the XV353 valve.

• After the cleaning sequence for the XV353 valve is finished, start cleaning the XV354 valve.

• After the cleaning sequence for the XV354 valve is finished, start cleaning the XV355 valve.

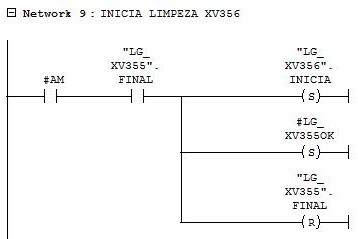

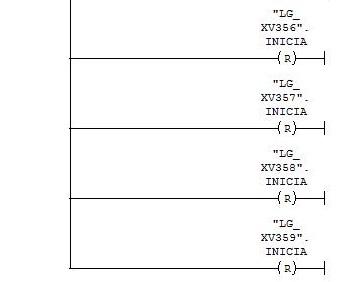

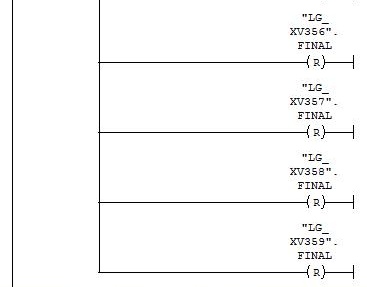

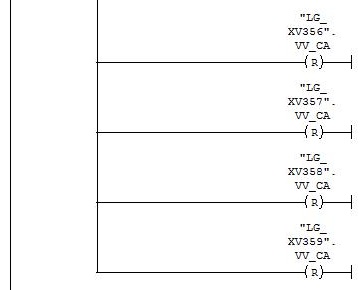

• After the cleaning sequence for the XV355 valve is finished, start cleaning the XV356 valve.

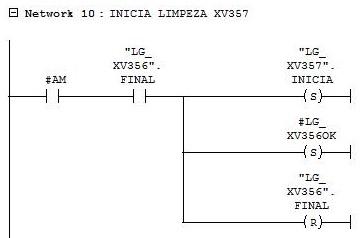

• After the cleaning sequence for the XV356 valve is finished, start cleaning the XV357 valve.

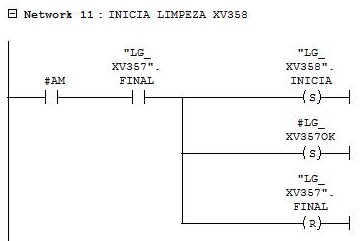

• After the cleaning sequence for the XV357 valve is finished, start cleaning the XV358 valve.

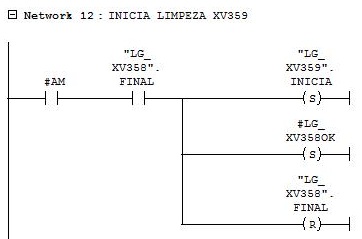

• After the cleaning sequence for the XV358 valve is finished, start cleaning the XV359 valve.

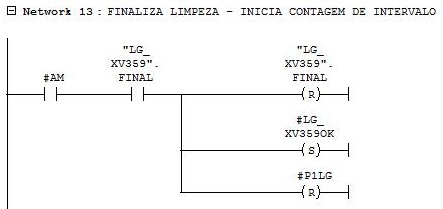

• After the cleaning sequence of the XV359 valve has finished, start counting the time interval between cleanings.

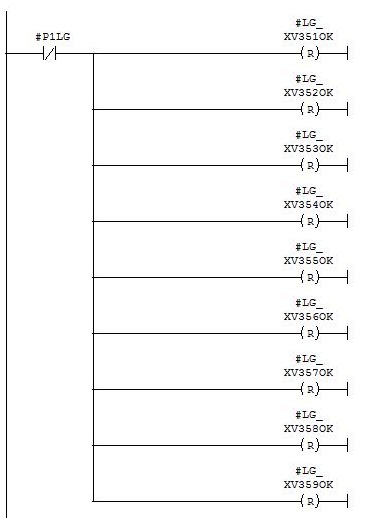

• Reset of the cleaning status of each valve.

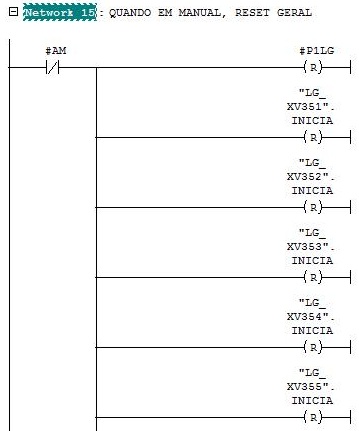

• General reset when the grid cleaning control is in manual.

• Transition pulse with grid cleaning control going from manual to automatic.

• Change auto/manual mode of all valves to automatic, the instant the grid cleaning control goes to automatic. After this moment, the valve's auto/manual mode can be changed to manual by the operator, even with the grid cleaning control in automatic.

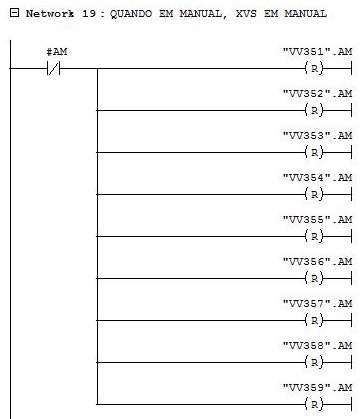

• Selection of auto/manual mode of the valves to manual when the grid cleaning control is in manual.

• With manual grid cleaning control, reset the automatic valve control.

• Function block instance FB_LIMP_VV for valve XV351. The VV_CA output activates the AC input parameter of the function block instance of the VV351 on-0ff valve.

| LG_XV351 | FB_LIMP_VV | DB62 |

• FB_LIMP_VV function block instance for XV352.

| LG_XV352 | FB_LIMP_VV | DB63 |

• FB_LIMP_VV function block instance for XV353.

| LG_XV353 | FB_LIMP_VV | DB64 |

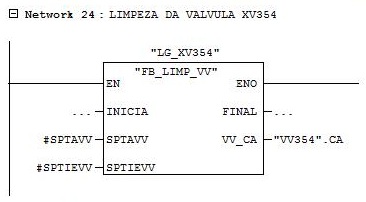

• FB_LIMP_VV function block instance for XV354.

| LG_XV354 | FB_LIMP_VV | DB65 |

• FB_LIMP_VV function block instance for XV355.

| LG_XV355 | FB_LIMP_VV | DB66 |

• FB_LIMP_VV function block instance for XV356.

| LG_XV356 | FB_LIMP_VV | DB67 |

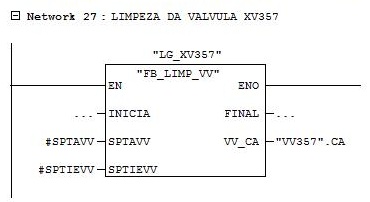

• FB_LIMP_VV function block instance for XV357.

| LG_XV357 | FB_LIMP_VV | DB68 |

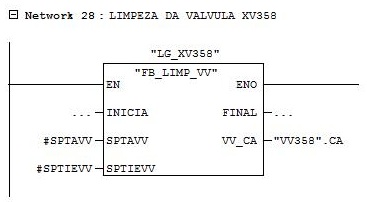

• FB_LIMP_VV function block instance for XV358.

| LG_XV358 | FB_LIMP_VV | DB69 |

• FB_LIMP_VV function block instance for XV359.

| LG_XV359 | FB_LIMP_VV | DB70 |

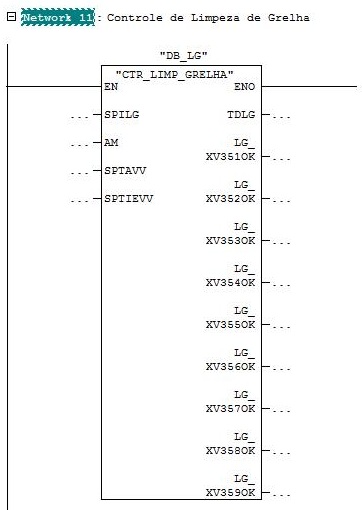

• Open OB1 and insert CTR_LIMP_GRELHA function block.

| DB_LG | CTR_LIMP_GRELHA | DB71 |

• Select Operator Control and Monitoring for DB71 DB_LG.

• Compile AS and OS.

• Create front for Grid Cleaning Control in the Controles.pdl.