SIEMENS SIMATIC S7 + WINCC

Superheater Ventilation Control

Superheater Ventilation Control

This mesh allows protection of the steam superheater against minimum boiler steam flow (30%) and high overheated steam temperature. Control is performed by measuring the flow (FT300) and temperature (TT300) of the steam, which send signal to the controller. The controller output signal acts directly on the ventilation control valve installed on the steam superheater.

When the vapor flow rate decreases (PV falls) below the safety minimum flow setpoint, the MV value should increase. When the steam flow increases (PV increases) above the minimum safe flow setpoint, the MV value should decrease.

When the steam temperature decreases (PV falls) below the safety temperature setpoint, the MV value should decrease (close valve). When the steam temperature increases (PV increases) above the safety temperature setpoint, the MV value should increase (open vent valve).

In manual, the valve opening value entered by the operator must feed both PIDs. This feature prevents a start to the valve opening when the control is put into automatic.

The automatic/manual valve mode commands the selection of automatic/manual PID modes.

• Create the following variables in the symbol table:

| Name | Address | Type | Description | S7_m_c |

|---|---|---|---|---|

| FCV300_AM | M1.0 | Bool | FCV300 Auto/Manual | True |

| FCV300_MV | MD48 | Real | FCV300 Valve openning command | True |

• Create a variable for opening the steam desuperheater valve in the symbol table.

| Name | Address | Type | Description | S7_m_c |

|---|---|---|---|---|

| FCV300_RB | MD52 | Real | Superheader ventilation valve READBACK | True |

• Create Function FC9 CTR_FCV300 VV Control Overheated Steam Vent. Right-click on the Blocks folder and select Insert New Object > Function menu item.

• Abrir function CTR_FCV300 e inserir function block FB_PID.

| FIC300 | FB_PID | DB59 |

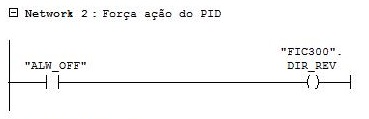

• Force PID action. When the steam flow decreases (PV drops) below the minimum safety flow setpoint, the MV value should increase. When the steam flow increases (PV increases) above the minimum safety flow setpoint, the MV value must decrease.

• Move the multiplication factor for converting PV and SP (0 to 300 ton/h) to 0 to 100% at the PID input.

• Create Function FC8 CTR_TT300 Superheated Steam Temperature Control. Right-click on the Blocks folder and select Insert New Object > Function menu item.

• Abrir function CTR_FCV300 e inserir function block FB_PID.

| TIC300_2 | FB_PID | DB60 |

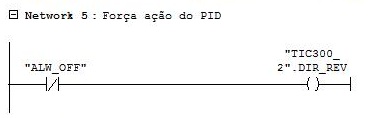

• Force PID action. When the steam temperature decreases (PV drops) below the safety temperature setpoint, the MV value must decrease (close the valve). When the steam temperature increases (PV increases) above the safety temperature setpoint, the MV value must increase (open valve for ventilation).

• Move multiplication factor to convert PV and SP (0 to 500 oC) to 0 to 100% at the PID input.

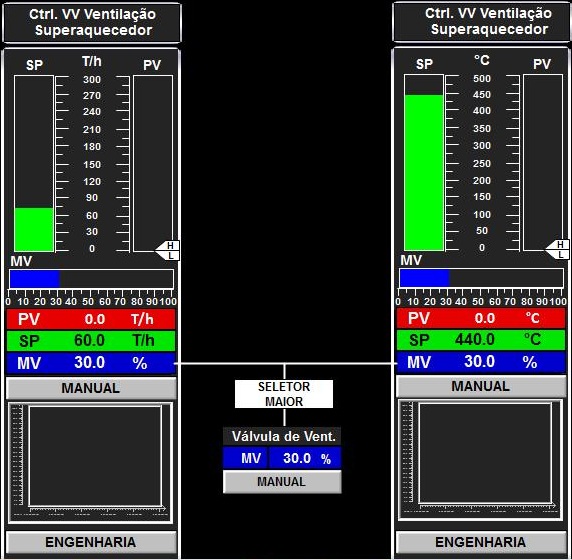

• In automatic, the PID with the highest value MV controls the valve. In this way, the control meets the safety requirements for minimum steam flow and maximum steam temperature in the superheater.

• In manual, the valve opening value entered by the operator must feed back the two PIDs. This feature avoids a start in the valve opening when the control is set to automatic.

• The automatic/manual mode of the valve controls the selection of the automatic/manual modes of the PIDs.

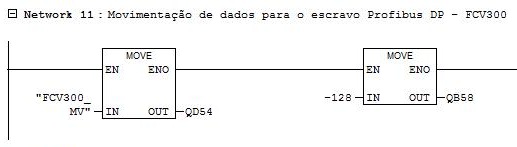

• Move the PID output to the FCV300 control valve on the Profibus-PA network.

• Read the opening value of the FCV300 control valve via the Profibus-PA network.

• Call FC9 CTR_FCV300 in OB1.

• Select Operator Control and Monitoring for DB59 FIC300 and DB60 TIC300_2.

• Compile AS and OS.

• Create front for PID Control VV Steam Superheated in Controle_Temperatura.pdl.

FIC300:

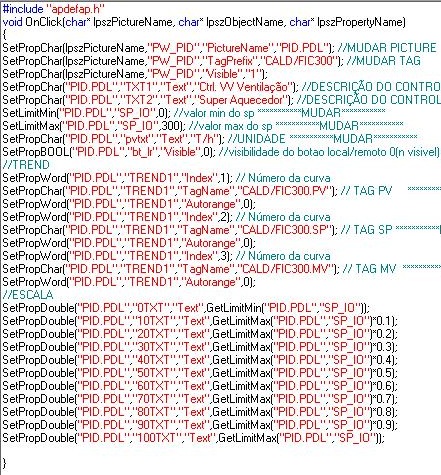

C script to show the PW_PID object in the current picture.

The Picture Name property of the PW_PID receives the name of the PID.PDL.

The TagPrefix property of the picture window PW_PID is set to CALD/FIC300. This instruction adds the text “CALD/FIC300” at the beginning of all dynamizations of objects within the picture window.

TIC300_2:

C script to show the picture window PW_PID object in the current picture.

The Picture Name property of the PW_PID picture window receives the name of the PID.PDL.

The TagPrefix property of the PW_PID picture window is set to CALD/TIC300_2. This instruction adds the text “CALD/TIC300_2” at the beginning of all dynamizations of objects within the picture window.