SIEMENS SIMATIC S7 + WINCC

Profibus DP

Boiler Project

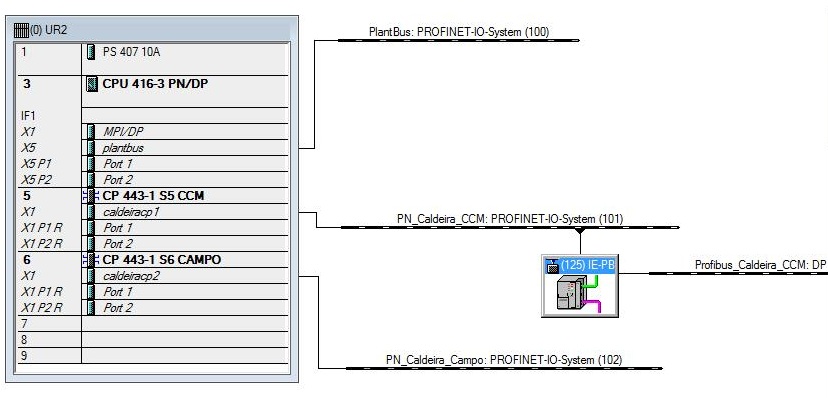

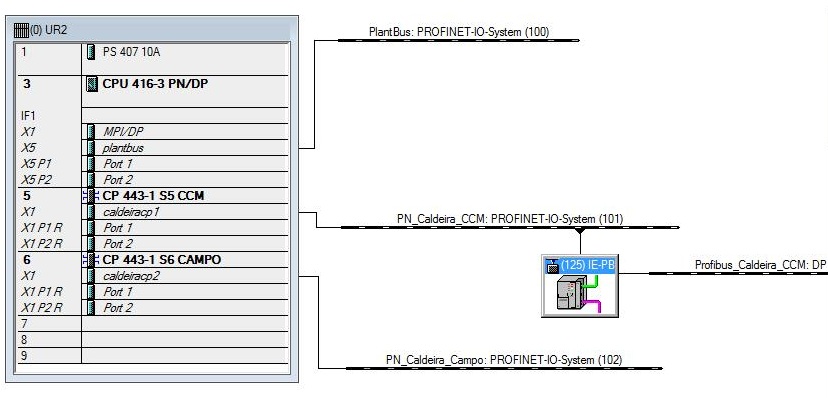

• Insert IE-PB Link 6GK1 411-5AB00 in the subnet PN_Caldeira_CCM (catalog - Profile Standard > PROFINET IO\Gateway\IE/PB Link PN IO\6GK7 411-5AB00). Click on item 2.1 and drag to the PN_Caldeira_CCM subnet.

Acting as an independent device, the IE / PB Link PN IO is the perfect link between Industrial Ethernet and Profibus. It operates with real-time communication (RT), which allows existing Profibus devices to be integrated into a Profinet application.

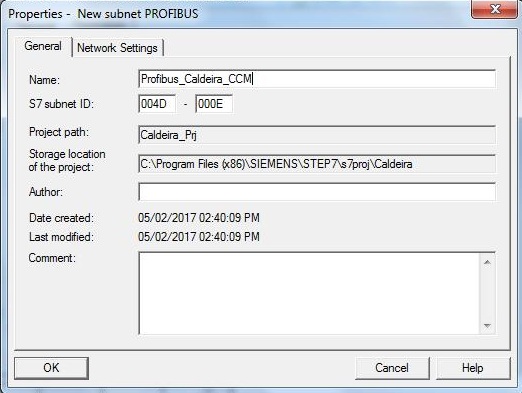

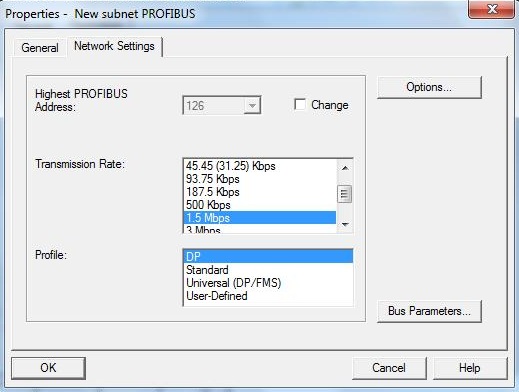

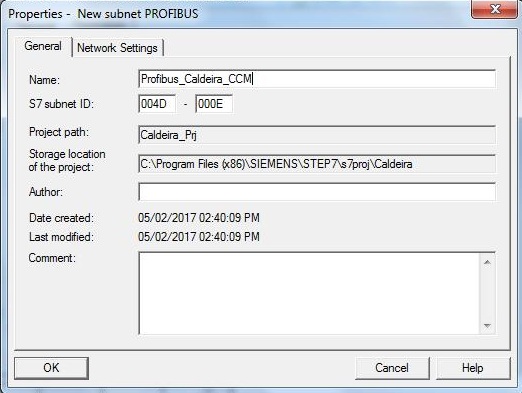

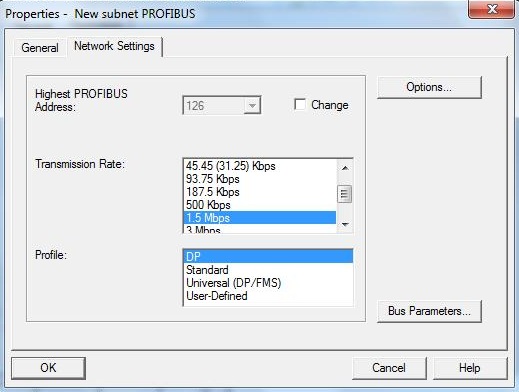

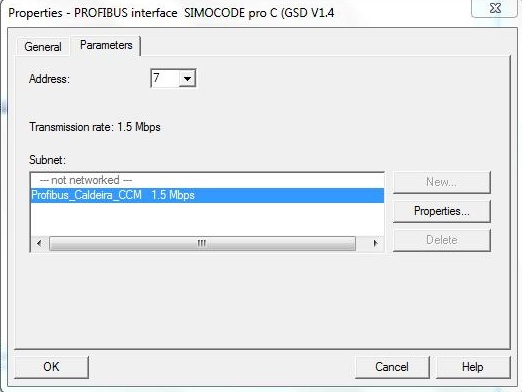

• Create the Profibus_Caldeira_CCM subnet. In the Network Settings tab, set the speed of the Profibus (Transmission Rate) subnet to 1.5 Mbps.

• Insert motors in the Profibus_Caldeira_CCM subnet. Motor drives of 3 types will be inserted:

1 - Direct starter – SIMOCODE pro C; Código: 3UEF 000-1A*00-0; GSD: SI0180.GSD

2 – Soft starter – SIRIUS 3RW44; Código: 3RW44**-*BC**; GSD: SIEM80DE.GSD

3 – Frequency inverter – MICROMASTER 4; Código: 6SE640X-1PB00-0AA0; GSD: SI0280B5.GSD

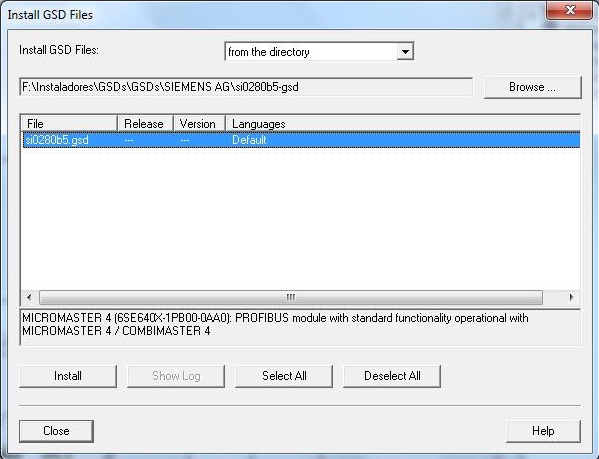

If any of these drives are not installed in your catalog, the GSD must be installed. To do this, follow the steps:

1 - Before installing the GSD file, close the current project in HW Config. Otherwise, an error message will appear. Open HW Config and select Station > Close menu item.

2 - Select Options > Install GSD File... menu item.

3 - Indicate the location of the GSD file (Browse button). Select the sub-folder where the GSD file (s) are located.

4 - Select the file (s) listed. Select All the GSD files in the subfolder.

5 - Click the Install button.

Boiler Project

• Insert IE-PB Link 6GK1 411-5AB00 in the subnet PN_Caldeira_CCM (catalog - Profile Standard > PROFINET IO\Gateway\IE/PB Link PN IO\6GK7 411-5AB00). Click on item 2.1 and drag to the PN_Caldeira_CCM subnet.

Acting as an independent device, the IE / PB Link PN IO is the perfect link between Industrial Ethernet and Profibus. It operates with real-time communication (RT), which allows existing Profibus devices to be integrated into a Profinet application.

• Create the Profibus_Caldeira_CCM subnet. In the Network Settings tab, set the speed of the Profibus (Transmission Rate) subnet to 1.5 Mbps.

• Insert motors in the Profibus_Caldeira_CCM subnet. Motor drives of 3 types will be inserted:

1 - Direct starter – SIMOCODE pro C; Código: 3UEF 000-1A*00-0; GSD: SI0180.GSD

2 – Soft starter – SIRIUS 3RW44; Código: 3RW44**-*BC**; GSD: SIEM80DE.GSD

3 – Frequency inverter – MICROMASTER 4; Código: 6SE640X-1PB00-0AA0; GSD: SI0280B5.GSD

If any of these drives are not installed in your catalog, the GSD must be installed. To do this, follow the steps:

1 - Before installing the GSD file, close the current project in HW Config. Otherwise, an error message will appear. Open HW Config and select Station > Close menu item.

2 - Select Options > Install GSD File... menu item.

3 - Indicate the location of the GSD file (Browse button). Select the sub-folder where the GSD file (s) are located.

4 - Select the file (s) listed. Select All the GSD files in the subfolder.

5 - Click the Install button.

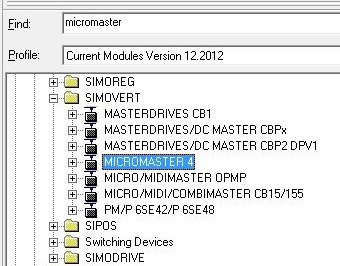

• The GSD will be loaded into the hardware catalog. The MICROMASTER 4 drive was loaded in the image.

The images related to GSDs in HW Config are stored in C:\Program Files (x86)\SIEMENS\STEP7\S7DATA\NSBMP.

Select the Standard profile in the catalog (the selection is made at the top of the catalog).

Motors

| Tag | Description | Type | Address |

|---|---|---|---|

| MT300 | Forced Air Fan | FI | 5 |

| MT305 | Induced Draft Fan | FI | 6 |

| MT311 | Soot Blower nr. 1 | DS | 7 |

| MT312 | Soot Blower nr. 2 | DS | 8 |

| MT313 | Soot Blower nr. 3 | DS | 9 |

| MT314 | Soot Blower nr. 4 | DS | 10 |

| MT306 | Ash removal thread | DS | 11 |

| MT301 | Bagasse Feeder nr. 1 | FI | 12 |

| MT302 | Bagasse Feeder nr. 2 | FI | 13 |

| MT303 | Bagasse Feeder nr. 3 | FI | 14 |

| MT304 | Bagasse Feeder nr. 4 | IF | 15 |

| MT307 | Pneumatic Distributor Fan | SS | 16 |

| MT101 | Bagasse Conveyor - Elevator | FI | 17 |

| MT102 | Bagasse Metal Conveyor - Distribution | IF | 18 |

| MT103 | Bagasse Conveyor - Leftover | FI | 19 |

| MT104 | Bagasse Metal Conveyor - Mountain | FI | 20 |

| MT105 | Bagasse Conveyor - Return | FI | 21 |

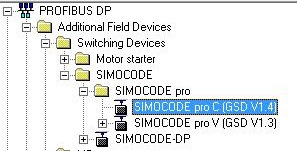

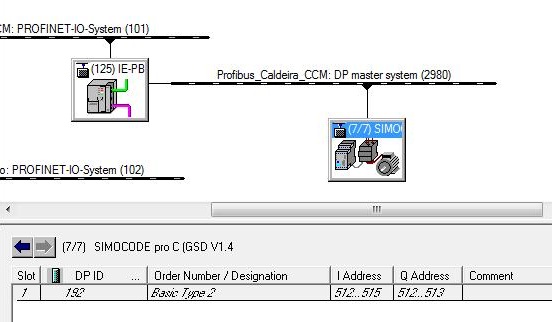

• Insert MT311 Soot Blower nr. 1 motor (SIMOCODE)

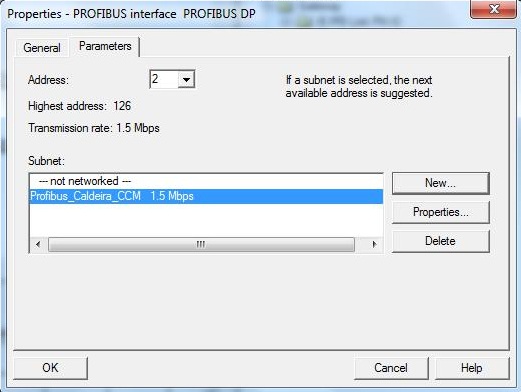

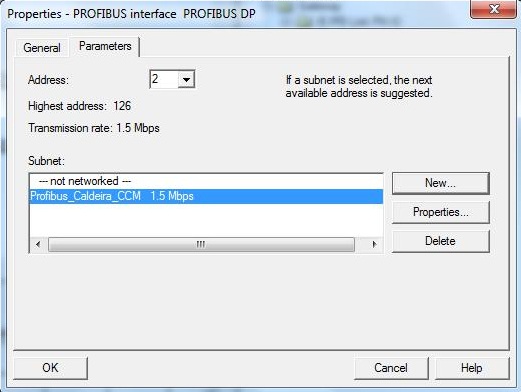

• Select SIMOCODE pro C in the catalog and drag it to the Profibus_Caldeira_CCM subnet. Set the Profibus-DP address to 7. Link the drive to the Profibus_Caldeira_CCM subnet.

• The I/O addresses (reading and writing cyclic data) automatically assigned to this drive were:

Input: I512...515 (4 bytes)

Output: Q512...513 (2 bytes)

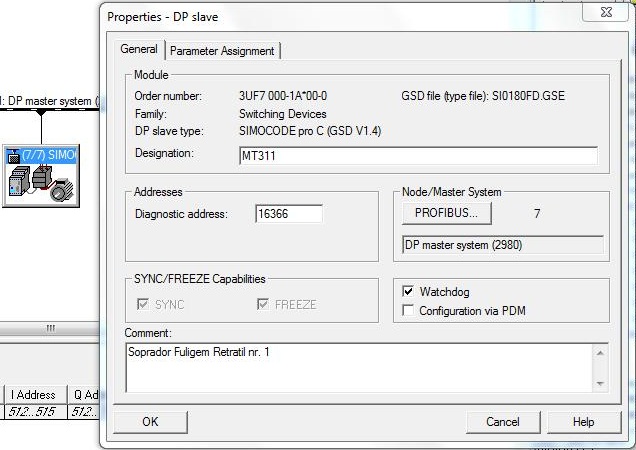

• I/O addresses can be changed. To do this, double click on line 1 (bottom of the image above). The following window will open:

• Open the properties of the Profibus-DP 7 slave and set the Designation field to MT311 and the Comment field to Soot Blower nr. 1.

• Repeat the procedures for the inclusion of the address 7 slave for the other direct starter motors:

| Tag | Description |

|---|---|

| MT312 | Soot Blower nr. 2 |

| MT313 | Soot Blower nr. 3 |

| MT314 | Soot Blower nr. 4 |

| MT306 | Ash removal thread |

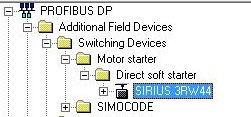

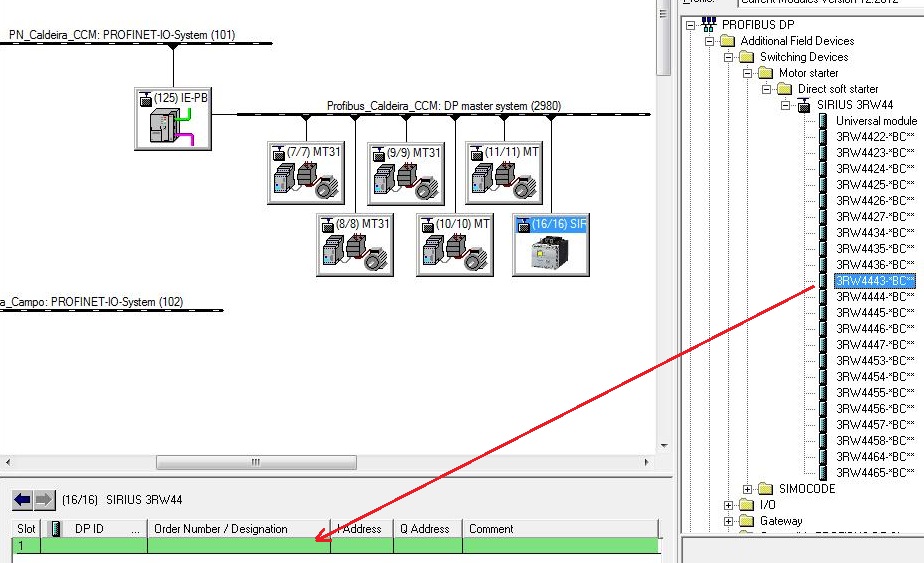

• Insert MT307 engine Pneumatic Distributor Fan (Softstarter)

• Select SIRIUS 3RW44 in the catalog and drag it to the Profibus_Caldeira_CCM subnet. Set the Profibus-DP address to 16. Link the drive to the Profibus_Caldeira_CCM subnet.

• The module for reading and writing cyclic data must be chosen from the options presented in the catalog, respecting the softstarter model. Choose module 3RW4443- * BC ** and drag it to the green area indicated in the image below.

• Change I/O addresses (reading and writing cyclic data) to:

Input: I532...533 (2 bytes)

Output: Q522...523 (2 bytes)

• Open the properties of the Profibus-DP 16 slave and set the Designation field to MT307 and the Comment field to Pneumatic Distributor Fan.

• Insert MT300 Forced Air Fan motor (MICROMASTER)

• Select MICROMASTER 4 in the catalog and drag it to the Profibus_Caldeira_CCM subnet. Set the Profibus-DP address to 5. Link the drive to the Profibus_Caldeira_CCM subnet.

• The cyclic data reading and writing module must be chosen from the options presented in the catalog. Choose 0PKW, 6 PZS (PPO 4) module.

• The I/O addresses (reading and writing cyclic data) automatically assigned to this drive were:

Input: I534...545 (12 bytes)

Output: Q524...535 (12 bytes)

• Open the properties of the Profibus-DP 5 slave and set the Designation field to MT300 and the Comment field to Forced Air Fan.

• Repeat the procedures for the inclusion of the address 5 slave for the other motors with frequency inverters:

| Tag | Description |

|---|---|

| MT305 | Induced Draft Fan |

| MT301 | Bagasse Feeder nr. 1 |

| MT302 | Bagasse Feeder nr. 2 |

| MT303 | Bagasse Feeder nr. 3 |

| MT304 | Bagasse Feeder nr. 4 |

| MT101 | Bagasse Conveyor - Elevator |

| MT102 | Bagasse Metal Conveyor - Distribution |

| MT103 | Bagasse Conveyor - Leftover |

| MT104 | Bagasse Metal Conveyor - Mountain |

| MT105 | Bagasse Conveyor - Return |

Profibus_Caldeira_CCM subnet: